في سوق البصريات الراقية، تم اختيار المسار الفني العدسات الفوتوكرومية يحدد بشكل مباشر تجربة المستخدم البصرية ومتانة النظارات على المدى الطويل. في الوقت ال...

READ MORE

سلسلة المنتجات

عدسة فوتوكروميك

-

1.56 عدسة فوتوكروميك SHMC

تُعرف العدسات الفوتوكرومية أيضًا باسم "العدسة الحساسة للضوء". وفقًا لمبدأ التفاعل العكس... -

عدسة بلو بلوك فوتوكروميك 1.56 HMC/SHMC

تتميز العدسات الزرقاء بطبقة خاصة تعكس الضوء الأزرق الضار وتمنعه من المرور عبر عدسة نظ... -

عدسة بولي كربونات فوتوكروميك 1.59 HMC/SHMC

الاسم الكيميائي لعدسة الكمبيوتر هو البولي كربونات، وهي مادة لدنة بالحرارة. تُسمى عدسة ا... -

عدسة فوتوكروميك 1.60 SHMC

تُعرف العدسات الفوتوكرومية أيضًا باسم "العدسة الحساسة للضوء". وفقًا لمبدأ التفاعل العكس... -

عدسة بلو بلوك فوتوكروميك 1.60 HMC/SHMC

عدسة المؤشر 1.60 أرق من عدسة المؤشر 1.499,1.56. بالمقارنة مع المؤشر 1.67 و1.74، تتمتع ا... -

1.67 عدسة فوتوكروميك SHMC

تُعرف العدسات الفوتوكرومية أيضًا باسم "العدسة الحساسة للضوء". وفقًا لمبدأ التفاعل العكس... -

عدسة بلو بلوك فوتوكروميك 1.67 HMC/SHMC

عدسة فوتوكروميك تغير لونها في ضوء الشمس. عادةً ما تكون صافية في الداخل وفي الليل وتتغير...

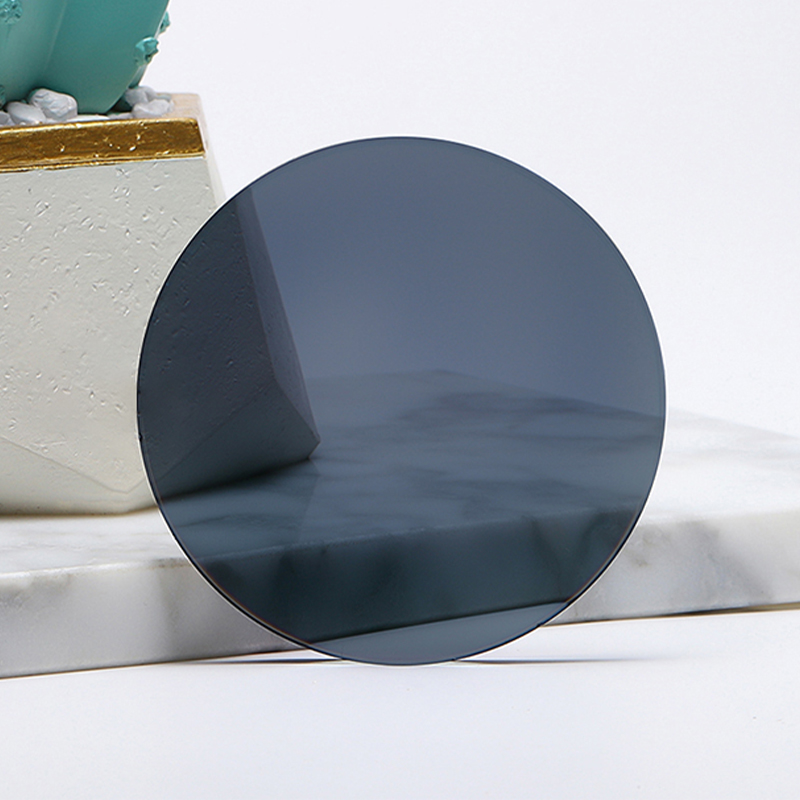

العدسة الفوتوكرومية هي عدسة ذات وظيفة تعتيم ذكية. يمكنه ضبط عمق لون العدسة تلقائيًا وفقًا لكثافة الأشعة فوق البنفسجية الخارجية. ويظل واضحًا وشفافًا في الداخل أو في البيئات ذات الأشعة فوق البنفسجية المنخفضة، وسرعان ما يصبح داكنًا في البيئات الخارجية ذات ضوء الشمس القوي أو الأشعة فوق البنفسجية الكافية. إنه يحجب بشكل فعال الأشعة فوق البنفسجية وتحفيز الضوء القوي، ويقلل من العبء على العينين، ويحسن وضوح الرؤية والراحة، ويمنع تلف العين ومشاكل الشيخوخة الناجمة عن الأشعة فوق البنفسجية. تحقق العدسة تفاعل تغيير لون سريع وقابل للعكس من خلال جزيئات ضوئية حساسة للغاية. سرعة تغيير اللون سريعة، ويتغير اللون بشكل طبيعي ومتساوي، ويتم استعادة الشفافية بسرعة، وتكون تجربة المستخدم سلسة. يتمتع المنتج بمقاومة ممتازة للطقس وقدرة على التكيف البيئي، ولا يزال يحافظ على أداء مستقر في ظل الظروف المناخية المعقدة مثل درجات الحرارة العالية ودرجات الحرارة المنخفضة وتغيرات الرطوبة. إنها مناسبة لمواد العدسات المختلفة مثل الراتنج والكمبيوتر الشخصي والنايلون وما إلى ذلك، ويمكن دمجها مع الاستقطاب والضوء المضاد للأزرق والمضاد للوهج والانعكاس ووظائف أخرى للمعالجة المركبة لتلبية الاحتياجات المهنية لمختلف المستخدمين في سيناريوهات متعددة مثل القيادة والرياضات الخارجية والتنقل اليومي والحماية الصناعية. وهو يدعم تخصيص الألوان والركائز المتعددة، مع ثبات عالي للألوان وليس من السهل أن يبهت بعد الاستخدام طويل الأمد.

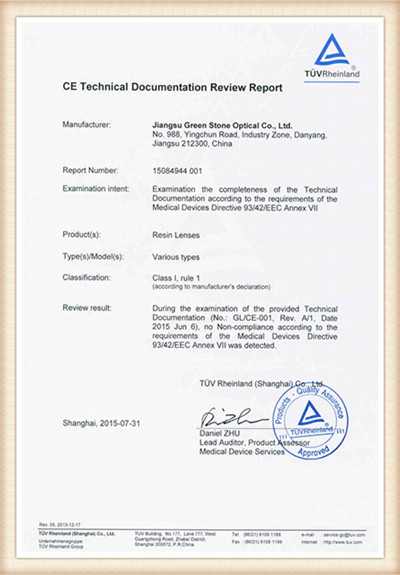

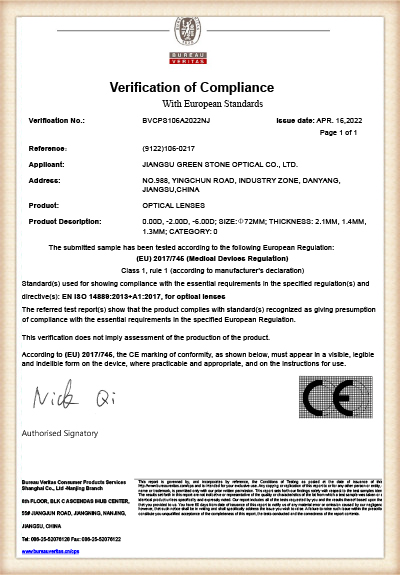

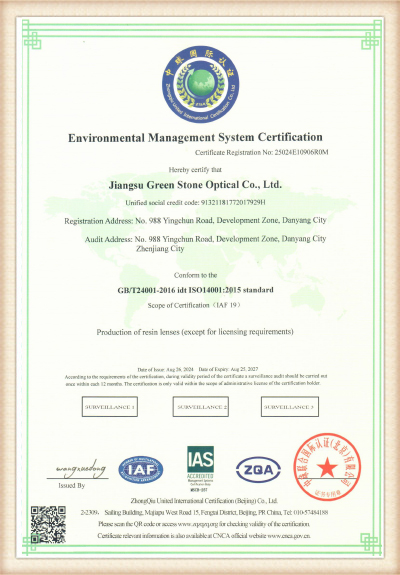

تشتمل منتجات العدسات لدينا على جميع أنواع العدسات تقريبًا. تغطي مجموعة المنتجات مؤشرات 1.499، و1.56، و1.60، و1.67، و1.70، و1.74، بما في ذلك الرؤية الفردية، وثنائية البؤرة، والتقدمية، والقطع الأزرق، والفوتوكروميك، والفوتوكروميك الأزرق، والقطع بالأشعة تحت الحمراء وما إلى ذلك مع معالجة HC وHMC وSHMC. إلى جانب العدسات الجاهزة، نقوم أيضًا بتصنيع الفراغات شبه الجاهزة. المنتجات مسجلة مع CE & FDA وإنتاجنا معتمد بمعايير ISO9001 و ISO14001.

نحن نقدم بشكل إيجابي تكنولوجيا الإدارة الممتازة، ونستورد نظام هوية الشركة بشكل شامل ونعزز الصورة الخارجية للشركة والعلامة التجارية.

-

-

في مجال قياس بصريات الأطفال، يتم مناقشة ما إذا كان يجب على الأطفال ارتداء النظارات أم لا العدسات الفوتوكرومية تطورت بشكل ملحوظ. مع التقدم في التكنولوجيا ...

READ MORE -

تطور التصحيح البصري: التنقل في اختيارات العدسات الخاصة بك لقد شهدت المتطلبات البصرية البشرية تغيرات ثورية خلال العقود القليلة الماضية. في الماضي، كانت النظارات تُست...

READ MORE -

ما هي العدسات متعددة البؤر والتقدمية؟ لتقدير قيمة حقا العدسات التقدمية ، فمن الضروري تحديد مكانها ضمن الفئة الأوسع للنظارات متعددة البؤر. العدسة متعدد...

READ MORE -

عدسة رؤية واحدة: دليل شامل لتصحيح الرؤية فهم عدسة الرؤية الواحدة: التعريف والمبادئ الأساسية أ عدسة رؤية واحدة هي النوع الأكثر أساسية والأكثر استخدا...

READ MORE -

عدسات نصف منتهية هي حجر الزاوية في النظارات الطبية المخصصة (Rx) في الصناعة البصرية. بالنسبة لمحترفي النظارات، يعد الفهم العميق لهيكل ووظيفة وموضع SFLs داخ...

READ MORE -

مقدمة للمفاهيم الأساسية: الغرض من العدسات المستقطبة والفوتوكرومية تم تصميم تقنيات العدسات المتقدمة لتعزيز الراحة البصرية وحماية العينين من الضوء الضار. من بين العدي...

READ MORE

What are the Working Principles of Photochromic Lenses

In the field of modern optics, photochromic lenses are undoubtedly a revolutionary innovation, perfectly combining traditional vision correction with intelligent light-adapting functionality. As a professional optical lens manufacturer with a strong combination of R&D, production, and sales, Jiangsu Green Stone Optical Co., Ltd. committed to providing high-performance, high-quality photochromic lens products to global users.

I. Core Scientific Principles of Photochromic Lenses

Photochromism, literally "light-color," refers to a material's reversible color change (darkening) when exposed to a specific wavelength of light (typically UV light). When the light weakens or is removed, the material reverts to a colorless or light-tinted transparent state. Photochromic lenses are designed and manufactured precisely based on this core principle.

1. Active Component: Photochromic Molecules

The essence of a photochromic lens lies in the photochromic molecules that are uniformly distributed within the lens substrate or on its surface. In plastic lenses, commonly used organic photochromic compounds include Naphthopyrans or Oxazines derivatives.

2. Darkening Process: Photochemical Reaction

When the lens is exposed to ultraviolet light (UVA/UVB) from the sun, the high-energy UV light excites the photochromic molecules, causing an isomerization reaction. Specifically, chemical bonds within the molecule break or rearrange, rapidly transforming its structure from a stable, colorless, or transparent "Closed Form" into a new "Open Form" that strongly absorbs visible light. It is this "Open Form" structure that absorbs portions of the visible spectrum, causing the lens to darken and providing sun protection.

3. Clearing Process: Thermal Recovery and Reversibility

Upon moving away from UV exposure, such as indoors or on a cloudy day, the photochromic molecules lose the UV excitation energy, and their new "Open Form" structure becomes unstable. The molecules spontaneously, or driven by thermal energy, rapidly reverse back to the original "Closed Form" structure. The lens gradually returns to its clear, transparent state, demonstrating the excellent reversibility of the photochromic technology.

4. Influencing Factors

The darkening depth and speed of photochromic lenses are primarily influenced by three factors: UV light intensity, ambient temperature, and the lens substrate material. Stronger UV light leads to deeper darkening. Higher temperatures accelerate the thermal recovery process, which can slightly reduce the maximum darkening depth.

II. Product Advantages and Technical Manifestation of Jiangsu Green Stone Optical Co., Ltd.

Leveraging its 65,000-square-meter production base and a professional team of over 350 employees, Jiangsu Green Stone Optical Co., Ltd. integrates cutting-edge photochromic technology into its products, demonstrating our professional capability and deep understanding of user needs.

1. Rich Product Series and High-Quality Assurance

Our product line covers the mainstream photochromic lens types on the market, including standard Photochromic and innovative Blue Cut Photochromic lenses. This means our products not only automatically adapt to changing light but also incorporate harmful blue light protection demanded by modern digital device use.

We offer a full range of refractive indices, from the conventional 1.56 to high-index options like 1.60 and 1.67, ensuring that consumers with both low and high prescriptions can find thin, aesthetically pleasing photochromic solutions. Our advanced production technology and molds guarantee the uniform distribution of photochromic molecules—whether integrated into the substrate or applied as a coating. This effectively avoids the issue of uneven color depth caused by varying lens thickness in traditional technologies, providing a smooth and consistent transition experience.

2. Superior Coating Technology for Enhanced Performance

Beyond the photochromic substrate itself, we offer various high-end surface treatments, including HC (Hard Coat), HMC (Hard Multi-Coat), and SHMC (Super Hydrophobic Multi-Coat). HMC and SHMC treatments, utilizing multi-layer optical coating technology, effectively reduce light reflection, increase light transmission, and enhance the lens's abrasion resistance. These treatments are crucial for maximizing the clarity of photochromic lenses indoors or at night, while also significantly increasing product lifespan and wearer comfort.

3. International Certification for Reliable Quality

Our products are CE and FDA registered, and our production processes are strictly certified under ISO9001 (Quality Management System) and ISO14001 (Environmental Management System) standards. These international certifications serve as a powerful testament to our professional manufacturing capabilities and form the foundation of consumer trust. Choosing photochromic lenses from Jiangsu Green Stone Optical Co., Ltd. means choosing stability, safety, and high international standards.

III. Practical Value for Users

Photochromic lenses from Jiangsu Green Stone Optical Co., Ltd. significantly enhance users' visual health and convenience:

- Two-in-One Lens, Ultimate Convenience: Seamless transition between indoor and outdoor environments eliminates the need to constantly switch glasses or carry prescription sunglasses, offering users a true "all-day" solution.

- Complete UV Protection: Our photochromic lenses block 100% of UVA and UVB rays, which is vital for preventing cataracts and protecting retinal health.

- Integrated Blue Light Cut, Comprehensive Eye Care: The Blue Cut Photochromic series further filters out harmful blue light, making it particularly suitable for users who spend extended periods on digital devices.

How Does the Photochromic Effect Differ Across Single Vision, Bifocal, and Progressive Lens Designs?

As a high-end application in modern optics, the core appeal of photochromic lenses lies in their "intelligent" ability to adapt to light. However, in different vision correction designs—such as Single Vision, Bifocal, and Progressive lenses—the realization, uniformity, and user experience of the photochromic effect involve specialized technical differences.

I. Review of Core Photochromic Technology and Implementation Methods

Photochromic lenses achieve their color change function by uniformly integrating photochromic molecules (Photochromic Molecules) into the lens substrate or coating them onto the surface. When exposed to UV light, the molecules undergo a reversible structural change, absorb visible light, and the lens darkens. When the UV light disappears, the molecules revert, and the lens clears.

Jiangsu Green Stone Optical Co., Ltd. possesses a 65,000-square-meter production base and has introduced complete sets of advanced equipment, new production technology, and molds. This allows us to flexibly adopt the most suitable photochromic technology for different lens designs:

1. In-mass Technology: Integrating photochromic molecules into the lens material itself.

2. Trans-bonding/Surface Coating: Applying a uniform, thin layer of photochromic molecules to the front surface of the lens.

In single vision, bifocal, and progressive lenses, the significant differences in their optical design and thickness distribution mean that these two implementation methods have distinct impacts on the final photochromic effect.

II. Technical Differences in Photochromic Effects Across Different Lens Designs

1. Single Vision Photochromic Lenses

- Design Characteristics: The entire lens has a uniform curvature and is used to correct a single focal distance (distance, near, or astigmatism). The lens thickness is relatively uniform or changes smoothly toward the edge.

- Differences in Photochromic Effect:

- Uniformity Advantage: Because the optical area of single vision lenses is complete and continuous, the distribution of photochromic molecules—whether achieved through in-mass technology or surface coating—is highly uniform across the entire effective area. Therefore, the color depth and darkening speed after activation are almost perfectly consistent across the lens.

- Thickness Influence: Even with in-mass technology, the relatively small variation in thickness of single vision lenses ensures well-controlled uniformity of the color change.

- Jiangsu Green Stone Optical Co., Ltd. Advantage: Our high-index single vision lenses, such as 1.56, 1.60, and 1.67, utilize optimized photochromic formulas and precision optical coatings (e.g., HMC, SHMC) to ensure fast darkening speed, consistent color depth, and simultaneous UV and harmful blue light protection (as with our blue cut photochromic series).

2. Bifocal Photochromic Lenses

- Design Characteristics: The lens is divided into two distinct areas by a visible line: the top for distance vision and an inset segment at the bottom for near vision (Add Power).

- Differences in Photochromic Effect:

- Segment Line Influence: The visible dividing line in bifocal lenses is a structural feature of the optical design. Although photochromic molecules are activated in both areas during darkening, the abrupt change in power and optical structure at the dividing line can cause the color transition to appear slightly discontinuous visually.

- Thickness Influence: The near segment is often created by increasing lens thickness or embedding a material with a different refractive index. If in-mass technology is used, the thicker near segment might theoretically darken slightly more than the distance portion.

- Jiangsu Green Stone Optical Co., Ltd. Solution: For bifocal designs, we favor advanced surface coating/trans-bonding technology. This ensures the photochromic layer is uniformly distributed over the entire lens surface, minimizing color non-uniformity caused by internal structural and thickness differences and guaranteeing a smooth color transition after darkening. Our CE&FDA registered products reflect our ability to precisely control complex designs.

3. Progressive Photochromic Lenses

- Design Characteristics: The lens has no visible dividing lines, with power gradually changing from top to bottom, including distance, intermediate, and near zones. This power change entails complex variations in thickness, curvature, and effective optical area.

- Differences in Photochromic Effect – The Highest Technical Challenge:

- Power Change and Thickness: Progressive lenses inevitably feature aspheric distortion and thickness variations on both sides of the optical corridor. If in-mass technology were used, the thickest part of the lens (often the near segment or periphery) would theoretically darken the most.

- Uniformity in the Visual Corridor: The core of a progressive lens is its seamless transition. The photochromic technology must be perfectly integrated with the complex free-form surface design to ensure that the color transition is as smooth and natural as the power transition, without compromising visual quality when looking through different zones.

- Jiangsu Green Stone Optical Co., Ltd. Technical Breakthroughs:

- Utilizing the advanced equipment and professional technology at our 65,000-square-meter production base, we custom-develop a high-precision, highly uniform surface-bonded photochromic process for progressive lenses.

- This process ensures that the photochromic layer adheres to the complex, multi-curve progressive surface in an extremely thin and highly uniform manner. This means the photochromic effect is primarily determined by UV intensity, not by the lens's inherent thickness variations, thus guaranteeing consistency in darkening depth and smoothness of transition across all visual zones (distance, intermediate, and near).

III. Comprehensive Product Commitment of Jiangsu Green Stone Optical Co., Ltd.

Jiangsu Green Stone Optical Co., Ltd. not only manufactures a full range of refractive indices (1.499 to 1.74) and various designs (single vision, bifocal, progressive) but also integrates photochromic technology into them, offering customers:

- Quality Assurance: Products are CE&FDA registered, and production is certified by ISO9001 & ISO14001, ensuring reliable product performance from the source.

- Coating Technology Upgrade: Our photochromic products can be fitted with high-end coatings such as HC, HMC, and even SHMC. These coatings not only enhance durability but also reduce reflection, guaranteeing optimal visual clarity in both the darkened and clear states.

Choosing photochromic lenses from Jiangsu Green Stone Optical Co., Ltd. means opting for a professional, efficient, and visually excellent "all-day" smart vision protection, regardless of the prescription design. We are committed to minimizing customer concerns regarding selection and usage through technical innovation, providing the highest value products to the global optical market.

What is the Relationship Between Photochromic Lens Transmittance, Color Depth, and Light Intensity?

Photochromic lenses are hailed as the "intelligent dimmers for the eyes," and their core value lies in the ability to automatically adjust light transmittance based on ambient light intensity. This dynamic adaptability is not a simple on/off mechanism but is rooted in precise physicochemical principles and high-standard manufacturing processes.

I. Transmittance and Color Depth: Core Metrics of Photochromic Lenses

Transmittance, in optics, typically refers to the Visible Light Transmittance, which is a crucial metric measuring how much visible light the lens allows to pass through to the eye. Color depth is the direct visual representation of transmittance.

1. Clear State (Indoor/Night): High Transmittance

In environments with weak UV light, such as indoors or at night, the photochromic molecules within the lens remain in their stable "Closed Form" and do not absorb visible light.

- Jiangsu Green Stone Optical Co., Ltd.'s Standard: We impose strict requirements on lens base color and coating technology. In the non-activated state, our photochromic lenses aim to achieve extremely high transmittance (close to or above 92%), ensuring visual clarity is uncompromised in low-light conditions. By applying our HMC (Hard Multi-Coat) and SHMC (Super Hydrophobic Multi-Coat) coatings, we maximize the reduction of surface reflections and light loss, further enhancing the lens's visual performance in its clear state.

2. Darkened State (Outdoor/Bright Light): Low Transmittance

When the lens is exposed to strong solar UV light, the photochromic molecules are activated into the "Open Form" and begin to absorb visible light. The more light absorbed, the darker the lens color becomes, and the lower the transmittance drops.

- Target: In the darkened state, the lens must reach a color depth sufficient for comfortable sun protection, typically reducing transmittance to the range of 20% to 40%, to effectively shield the eyes from intense light stimulation.

II. The Dynamic Functional Relationship Between Color Depth and Light Intensity

The photochromic reaction is a dynamic process directly correlated with light intensity, which highlights its "intelligent" nature.

1. UV Light as the Primary Driving Force

The photochromic reaction is mainly driven by UV light (especially UVA). The intensity of UV radiation in the light is the key factor determining the number of photochromic molecules activated and their activation speed.

- Positive Correlation with Intensity: The photochromic lenses from Jiangsu Green Stone Optical Co., Ltd. follow a strict response curve: the higher the outdoor UV intensity, the more molecules are excited, and the faster and deeper the lens darkens, leading to lower transmittance. Conversely, on cloudy days or when shielded by clouds, the reduced UV intensity results in a lighter darkening degree, maintaining moderate transmittance for clear vision.

2. Darkening and Clearing Speed: Crucial Performance Indicators

In addition to maximum darkening depth, the speed of darkening and clearing is another core indicator of photochromic lens quality.

- Darkening Speed: When moving from indoors to outdoors, excellent lenses (such as our high-index 1.60 and 1.67 photochromic products) should start to visibly darken within a few seconds, reaching about 80% of their maximum depth within 1-2 minutes, providing instant light protection.

- Clearing Speed: When moving from outdoors back indoors, the photochromic molecules must quickly revert. If the clearing speed is too slow, customers will experience the inconvenience of dim vision indoors. Jiangsu Green Stone Optical Co., Ltd. utilizes optimized photochromic molecular technology and precise formulations to ensure efficient clearing, minimizing the time required to recover from a dark state to high transmittance, significantly enhancing user experience and effectively reducing customer website bounce rates due to discomfort.

III. Additional Influence of Temperature and Product Technology

1. Temperature Influence (Thermal Recovery Mechanism):

The recovery (dark-to-clear) of photochromic molecules is a thermally activated process. In high-temperature environments, the molecular recovery speed accelerates, which means the lens's maximum darkening depth may be slightly less than in colder conditions. This is an inherent property of photochromic materials.

- Technical Advantage: Jiangsu Green Stone Optical Co., Ltd. is committed to researching and introducing new photochromic molecules to maximize the reduction of temperature influence on the maximum darkening depth, ensuring that our lenses provide sufficient shading even during hot summer weather.

2. Synergistic Effect of Coatings:

Our photochromic lenses can be selected with professional coatings like HC, HMC, and SHMC. While these coatings do not directly affect the photochromic mechanism, they are vital for transmittance. Especially our blue cut photochromic series, in the clear state, they filter harmful blue light, and when darkened, they provide both blue light protection and strong light attenuation, maximizing their functional combination.

What Process Requirements Must Be Observed When Processing Photochromic Lens Semi-finished Blanks?

The photochromic lens is the culmination of modern optical technology and material science. Its stability and reliability depend not only on the initial quality of the lens blank but also on the precision processing of the subsequent Semi-finished Blanks. As a professional optical lens manufacturer, Jiangsu Green Stone Optical Co., Ltd. not only offers a full range of refractive indices (1.499 to 1.74) and lens types, including Photochromic and blue cut photochromic, but also stands as a key manufacturer of high-quality semi-finished blanks. We deeply understand the special requirements and critical technical control points involved in processing photochromic blanks.

By detailing the processing requirements for photochromic blanks in this industry news piece, we aim to demonstrate the professional depth and technical standards of Jiangsu Green Stone Optical Co., Ltd. at the supply chain front end, effectively building customer trust and reducing website bounce rates.

I. Unique Challenges and Core Process Requirements for Photochromic Blanks

The distinct nature of photochromic blanks lies in the UV-sensitive photochromic molecules contained within or on their surface. Any rough or inaccurate processing could disrupt the uniformity of these molecules, compromising the final lens's photochromic performance and optical quality. Therefore, their processing must adhere to standards even stricter than those for ordinary clear lenses.

1. Temperature Control: The "Lifeline" of Photochromic Molecules

The recovery of photochromic molecules (dark to clear) is a thermally activated process. High temperatures accelerate their degradation and can impair the final color depth and lifespan.

- Process Requirement: Strict control over localized surface temperatures is essential during grinding, polishing, and cleaning processes.

- Professional Detail: Jiangsu Green Stone Optical Co., Ltd. mandates the use of low-temperature coolants and precisely controlled turning speeds in the surfacing lab to prevent frictional heat generated during grinding from activating or damaging the photochromic molecules. This is especially critical when grinding resin materials (e.g., 1.56, 1.60), where the material's low thermal conductivity increases the risk of localized heat generation, requiring more refined parameter settings.

2. Stress Control: Assurance of Optical Performance and Durability

If mechanical stress during the lens processing is poorly controlled, it can induce structural changes within the lens, affecting the final wearing comfort and durability.

- Process Requirement: High-precision clamps and moderate clamping force must be used to avoid introducing permanent stress at the lens edges and center during the surfacing and polishing stages.

- Advantage Manifestation: Our registration with CE&FDA and certification with ISO9001 ensure that every stage, from blank to finished product, adheres to the highest optical standards. This is particularly crucial for processing progressive blanks, as any introduced stress could distort the complex progressive surface design, affecting the seamless visual transition across the distance, intermediate, and near zones.

II. Curvature Accuracy and Precision of Optical Center Positioning

The processing of semi-finished blanks involves shaping the back surface to the customer's prescription, achieving the necessary power correction.

1. Curvature Accuracy

- Process Requirement: For all lens types, especially high-index photochromic lenses (e.g., 1.67, 1.70, 1.74), ultra-precision turning and polishing equipment are required to accurately create aspheric or free-form surface designs, ensuring precise power.

- Jiangsu Green Stone Optical Co., Ltd.'s Commitment: We invest in introducing complete sets of advanced equipment and new production technology to ensure minimal surface deviation in the finished lens. For the bifocal and progressive blanks we manufacture, the accuracy of the back surface curvature directly determines the final prescription accuracy, ensuring the optical performance of complex designs is perfectly realized.

2. Optical Center and Photochromic Uniformity

- Process Requirement: The optical center of the blank must be precisely measured and positioned as the benchmark for back surface processing.

- Professional Correlation: For blanks using surface coating technology for photochromism, the photochromic layer is on the front surface. The precision of the back surface processing does not directly damage the front layer, but if the optical center is wrongly positioned, the resulting photochromic optical performance may be misaligned, impacting wearing comfort. Jiangsu Green Stone Optical Co., Ltd. adheres to strict international standards for positioning, ensuring the photochromic function and the vision correction function are perfectly integrated.

III. Pre-Coating Surface Treatment and Cleaning Standards

After processing, photochromic lenses typically undergo HC, HMC, or SHMC coating treatments.

1. Surface Cleanliness

- Process Requirement: Before coating, the lens surface must achieve atomic-level cleanliness, completely removing all residual polishing compounds, oils, and chemical residues.

- Importance: Any minuscule residue will affect the adhesion and durability of the subsequent HMC/SHMC coating layers. Particularly for photochromic lenses, excellent coating quality is key to maintaining high light transmission and extending lifespan. Jiangsu Green Stone Optical Co., Ltd. employs multi-stage ultrasonic cleaning and specialized surface activation treatments to ensure our coating quality meets leading international standards.

2. Edge Processing: Aesthetics and Safety

- Process Requirement: For high-prescription blanks (especially high-index 1.67, 1.74), fine edge processing is necessary to enhance the final aesthetic when mounted in frames.

Jiangsu Green Stone Optical Co., Ltd., supported by a strong production base of 65,000 square meters and over 350 specialized employees, consistently adheres to professional and rigorous process requirements in the manufacturing of photochromic lens semi-finished blanks. Our strict control over key elements like temperature, stress, and precision is the foundation for our products' stable global export and market recognition. We are not just a supplier of finished lenses but a professional source manufacturer of optical solutions, ensuring that every lens, from blank to finished product, meets our commitment to outstanding quality.